Table of Contents

French military first used lanyards in the 15th century, and they’ve evolved significantly since then.

The choice between nylon and polyester materials stands out as a crucial decision for modern lanyard buyers.

Polyester lanyards dominate the market because they’re durable and affordable.

Nylon lanyards showcase a shinier look and resist weather damage better.

You can order polyester lanyards in small batches of 100 units. Nylon requires larger orders starting at 500 units but excels in wear resistance, stress management, and color retention.

Let’s explore which material matches your requirements by scrutinizing their strength, upkeep needs, and real-world uses.

This post will guide you through essential details about these leading lanyard materials that help plan corporate events or create business promotional items.

Understanding Lanyard Materials

Modern lanyard manufacturing relies mainly on polyester and nylon, each with unique features for different uses.

Polyester lanyards lead the market because they balance durability with economical solutions. Nylon lanyards stand out with their smooth ribbed appearance and silky, lustrous finish.

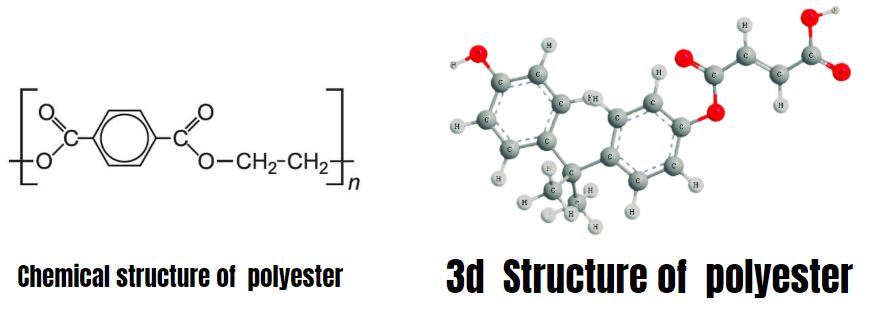

These materials differ at a chemical level.

Nylon is part of the polyamide polymer family and shows excellent resistance to wear, heat, and chemicals due to its high molecular weights.

Polyester, made mostly of PET (polyethylene terephthalate), works better at resisting water.

Each material’s manufacturing process takes a different path.

Polyester lanyard production starts with careful raw material selection and weaving on specialized looms. The steps involve:

- Material preparation and weaving

- Logo printing using silk-screen technology

- Deodorization in ventilated areas

- Cutting according to specifications

- Installation of accessories

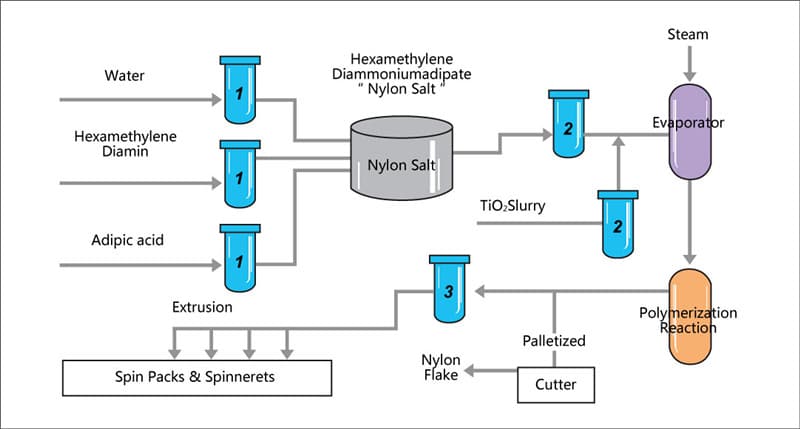

Nylon lanyard production needs more careful temperature control.

The ironing temperature must stay under 140°C, while polyester can handle up to 180°C. Nylon’s superior colorfastness, stress handling, and wearing resistance make it stand out.

These complex manufacturing requirements explain nylon lanyards’ higher cost compared to polyester ones.

Quality testing happens before final assembly for both materials. The finished products get specific treatments based on their intended use. Nylon works especially well when you have chemical exposure and need durability.

Polyester proves ideal for uses that need wrinkle resistance and dimensional stability.

Scientific Durability Testing

Lab tests show key differences in how durable nylon and polyester lanyards are. Scientific analysis helps us determine which material works better in different conditions.

Tensile Strength Comparison

Break strength tests show polyester lanyards have slightly better tensile strength than nylon ones.

A 1-inch polyester strap can handle breaking strength of 3,000 to 5,000 pounds.

Nylon straps match this performance well and reach 3,000 to 4,000 pounds breaking strength.

Nylon’s elasticity stands out as it stretches 20-30% at breaking point, while polyester only extends 5-15%.

Abrasion Resistance Tests

The Martindale method testing, run under 12 kPa load for 25,600 cycles, shows clear wear patterns.

Nylon proves excellent at resisting abrasion with “very slight abrasion” after the full test.

Under the same conditions, polyester shows “moderate abrasion”, which suggests it doesn’t handle continuous friction as well.

UV Exposure Effect

UV exposure tests reveal key differences in how these materials break down.

Nylon keeps 90% of its original breaking strength at first, while polyester maintains 80%.

After four months in UV exposure, both materials weaken similarly – nylon drops to 69% and polyester to 68% of original strength.

The largest longitudinal study beyond one year shows that polyester keeps more of its strength than nylon.

| Material | Initial Strength Retention | 4-Month Retention |

|---|---|---|

| Nylon | 90% | 69% |

| Polyester | 80% | 68% |

Environmental Factors

External conditions substantially affect how long lanyard materials last and how well they work in different settings.

Temperature Effects on Longevity

Kevlar-webbed lanyards work best in high-temperature environments and stay strong at temperatures up to 900°F.

Polyester webbing’s strength drops between 300°F and 400°F.

Both materials work reliably at normal temperatures. Special coatings protect the hardware parts up to 350°F to improve safety in extreme heat.

Moisture and Humidity Impact

Polyester resists moisture better than nylon.

Both materials stand up to water, but polyester’s water resistance gets better with higher thread counts. Nylon soaks up water faster, which can make it temporarily weaker when wet.

Both materials handle saltwater well and resist fading in marine settings.

Chemical Exposure Resistance

Polyester lanyards handle chemicals better, which makes them perfect for industrial use.

Regular polyester web lanyards resist wear and tear well and are easy to clean.

Polyester’s ability to withstand harsh chemicals and cleaning agents gives it an edge. The material stays strong against environmental hazards like:

- Corrosive environments

- High-voltage areas

- Industrial gasses

- Moving machinery zones

The lanyard will last longer if you store it away from chemicals and extreme temperatures.

Real-World Durability Analysis

Lanyard materials show their true value in companies and organizations of all types.

Different materials perform uniquely based on where and how people use them.

Industry Usage Studies

Companies of all sizes use polyester lanyards for employee IDs.

These lanyards resist wrinkles and mildew, which makes them perfect for office settings. Nylon works better outdoors because it resists water and bends easily.

Sports teams choose nylon lanyards because they hold up well during movement.

Customer Satisfaction Surveys

Recent surveys show that polyester lanyards score high marks for everyday durability.

Business customers keep their polyester lanyards in good shape with minimal maintenanc.

Customer feedback highlights nylon lanyards’ performance at prestigious events.

Groups that use lanyards outdoors are happier with nylon’s ability to withstand weather.

Long-term Wear Patterns

Studies over time show how different materials wear down differently.

Polyester lanyards look good longer and don’t fade much with regular use. Nylon ended up performing better in:

- Resisting tears during heavy use

- Bending in different conditions

- Standing up to outdoor weather

Both materials last a long time. Polyester resists stains better and dries faster.

Field tests prove that nylon keeps its shine even after long-term use. This makes it a great choice for professional environments where looks are vital.

Comparison Table

| Characteristic | Nylon Lanyards | Polyester Lanyards |

|---|---|---|

| Appearance | Smooth ribbed with silky, lustrous finish | Standard appearance, less shine |

| Breaking Strength | 3,000-4,000 pounds | 3,000-5,000 pounds |

| Stretch at Breaking Point | 20-30% | 5-15% |

| Original UV Strength Retention | 90% | 80% |

| 4-Month UV Strength Retention | 69% | 68% |

| Abrasion Resistance | Minimal wear after testing | Moderate wear after testing |

| Moisture Resistance | Absorbs more water | Better moisture resistance |

| Temperature Tolerance | Below 140°C (ironing) | Up to 180°C (ironing) |

| Chemical Resistance | Good | Excellent |

| Minimum Order Quantity | 500 units | 100 units |

| Best Applications | Premium events, outdoor activities, sports | Business settings, daily ID needs, industrial use |

| Main Benefits | Enhanced durability, stress handling, color retention | Economical solutions, wrinkle-free, stain-resistant |

| Maintenance | Needs more care | Easy to maintain |

Tests and real-life applications show clear differences between nylon and polyester lanyards.

Polyester boasts impressive breaking strength that reaches 5,000 pounds and resists chemicals well.

Nylon shines with its natural gleam and stretches 20-30% before breaking.

Lab tests prove polyester’s strength against UV rays, which makes it perfect for outdoor corporate events.

Nylon works best in professional settings where looks and stress handling matter most, though it requires larger orders.

Your specific needs will determine which material works best.

Polyester gives great value for everyday corporate use because it stays wrinkle-free and needs little care.

Nylon costs more but proves its worth when you need weather resistance and flexibility.

Want to pick the right lanyard? Our team at cheap-lanyard-supplier.com can help match the perfect material to what you need, all at competitive prices.